The History of Wairere

&

Surrounds

THE HOKIANGA

Is a region surrounding the Hokianga Harbour in the Far North of New Zealand. It is sparsely populated and has many little clusters of houses in a rural setting. Its full Māori placename is Hokianga-nui-a-Kupe - the returning-place of Kupe, the legendary polynesian discoverer of Aotearoa. Maori Legend has it that "Wairere was one of the eleven taniwha sons of Araiteuru (Āraiteuru) of Hokianga Harbour. His brothers, sent by their mother, all took it upon themselves to see who could burrow the furthest to see the country in which they lived.

Wairere followed the path cut by his brother Waihou and changed direction before he reached Horeke. He encountered a rough patch of land filled with boulders. Wairere found that the boulders were interesting shapes, and he wanted to bring one back to prove his story.

Unfortunately, the boulder proved exceptionally heavy, and he made it back to Waihou's path. There, exhaustion overtook him, so he fell asleep with the boulder still atop his head. He has not yet shaken the load from his shoulders, so he remains there, sleeping most of the time from the weight over his head. Even to this day, waka (ships, canoes) may be upset by this stone if Wairere stirs in his sleep, or, worse yet, if he half-awake attempts to take revenge for his plight.

The icon for the Hokianga is the Kauri tree. 75 % of all Kauri are in the Hokianga, which has four protected Kauri forests (Waipoua in the South-West, Omahuta to the North-East, Warawara in the North-West and Puketi in the East."

https://www.blackdrago.com/fame/wairere.htm

WAIRERE

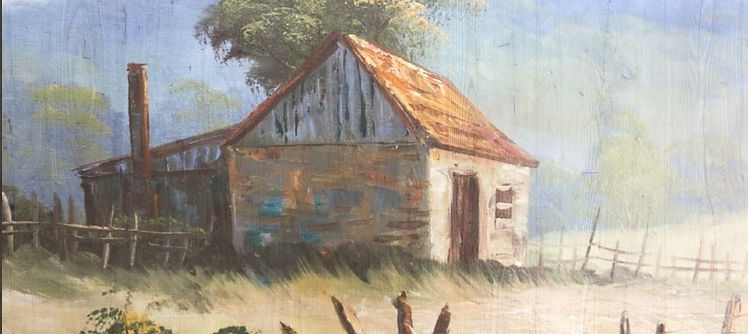

The Wairere Boulders property itself shares in the early history of the region. At the tip of the campground (on the estuary) is the site of NZ's first water powered sawmill, which was built by William Webster circa 1840, Water was diverted from near the current swimming hole several hundred metres upstream via an open wooden sluice to a height of 25 feet (~8 metres) above the sawmill's waterwheel.

William Webster came to own the Wairere property through marriage to Annabella (or 'Hana'), whose mother was a close relative of the great Chief Tamati Waka Nene. Annabella's father was Colin Gillies, a Scotsman who arrived in 1825. The marriage of the Gillies is the first known legal marriage between Maori and Pakeha in NZ.

HOREKE

The closest settlement to Wairere is the oldest Hokianga settlement and second oldest European settlement in New Zealand. Horeke has a rich Maori and European history, with evidence of Maori occupation dating back hundreds of years. Originally named Detford after a shipping yard in England, three ships of more than 100 tons were built before 1830, making Detford (NZ) the leading ship building centre in NZ. The name soon reverted to Horeke, 'the throwing of the spear'.

The original Horeke Tavern was built in 1826 and this original hotel construction still forms part of the hotel today, making this the oldest hotel in NZ. Given its prominence, the hotel was the site of the first government organised hui. Governor Hobson trudged for six days to reach Horeke with the freshly inked Treaty of Waitangi. The balance of the Northland chiefs signed at the nearby Mangungu Mission station and then it was celebration time in the pub grounds on the waters edge.

The Postal Service also has its origins here, with a horseback service between the Hokianga and the Bay of Islands starting three months after the Treaty signing.

European settlement at Horeke began in the early 19th century and the town grew as a centre for shipbuilding and timber milling. In the mid-19th century, Horeke was a bustling port town, with ships carrying kauri timber and other goods to and from Auckland. Today, many of the town's historic buildings and landmarks are preserved, including the Horeke Tavern, but there is little commercial activity.

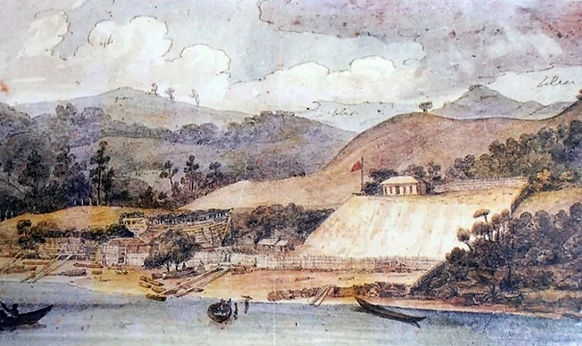

Horeke Shipyard 1826 by August Earle - Print hanging in the Horeke Hotel

This drawing, by missionary Richard Taylor, shows the feast to celebrate the third treaty-signing ceremony, at the Mangungu mission house, south Hokianga. The feast, on 13 February 1840, was held on the property of the shipbuilder Thomas McDonnell at nearby Hōreke. Cannon protect the harbour, in which many waka can be seen. A large crowd is gathered at left, under several Union Jack flags. Alexander Turnball Library, Reference: E-296-q-169-3

Drawing by Richard Taylor

Māngungu

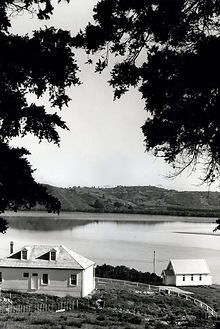

Was established on the shore of the Hokianga Harbour in 1828 as a Wesleyan Mission station. It was re- built in 1838-1839 for the Reverend Nathaniel Turner after a fire. It is a simple building that looks out over the beautiful Hokianga Harbour, a serene scene that belies the sometimes turbulent history of the area.

Following lengthy discussions, the largest signing of the Treaty of Waitangi in the country took place here, with over 70 chiefs adding their assent before a crowd of up to 3,000 people. The event is remembered each year on 12 February.

The first honey bee hives in New Zealand were established at the Mission in March 1839; Mary Bumby, who had arrived at the site with her missionary brother that month, had brought two hives with her. This led to the production of the first honey in the country. providing a major contribution to the success of pastoral farming in New Zealand. Today you can still get locally produced honey from hives at the Wairere Boulders (ask the Caretaker if we have some).

From 1840, the mission house was occupied by the Reverend John Hobbs and his family. Hobbs had drawn the plans for the house – a single-storey structure in a symmetrical, Georgian style – and supervised its construction from local kauri.

The family left Māngungu for Auckland in 1855 and the house was moved to Onehunga where it was used as a Methodist parsonage before being sold to private owners. The mission house was then returned to the Māngungu site in the 1970s, restored on behalf of Heritage New Zealand, and opened to visitors in 1977

.jpg)

Mangungu Mission house with St John’s Community Church

Mangungu Mission - founded in 1828

Wairere Boulders

Wairere Boulders was initially developed as a tourist attraction by Felix and Rita Schaad, a couple originally from Switzerland who owned the property from 1983 to 2017. They opened the 140 hectare (355 acre) site for visitors in 2000, after 4 years hard work developing tracks, bridges and lookouts.

Bruce Haywood, renowned NZ Geologist, describes the Boulders: "The biggest area of accentuated fluting on basalt rock in New Zealand. Basalt karst is rare worldwide. One of the best examples of a boulder-filled valley system in New Zealand, with unusual erosional processes at work."

For a geological history of The Boulders click Here

Rita and Felix Schaad

Wairere Treasure Trove

A Swiss couple discover a rare geological treasure on their Northland property.

Radio New Zealand Interview

Click on pictures to enlarge

Swiss-born Rita and Felix Schaad bought an old Northland dairy farm only to discover that it contained rare and spectacular formations of 'fluted' basalt rock.

Since then they’ve spent years of hard labour… building bridges and pathways through the valley of rocks, to turn it into a tourist attraction. Now thousands come to “Wairere Boulders” each year. NZ Herald 2015

The couple captured wild goats on their property to farm them for the fibre, and in the process found the big eroded basalt boulders lining the valley. The Schaads have laid out a boulder loop boardwalk, a “Dragon’s Cave” and a bush pool in the “Nikau Forest”. Walking at a slow pace a visitor can spend as little as twenty minutes or as much as two hours there. NZ Herald 2015. https://www.rnz.co.nz/national/programmes/spectrum/audio/201765233/wairere-treasure-trove

'MIDRIFF' A short film shot entirely in the Far North at Wairere Boulders - 2019

Click on pic above for full movie details

'Midriff' A short film shot entirely in the Far North at Wairere Boulders has been selected for screening at one of Mexico's top film festivals. Sept 2019

Click picture to enlarge

Scene from 'Midriff' with the Magic Rock, Wairere Boulders.